For industries requiring to record inventory and sales by Lot Numbers, Aralco has a solution so you can receive items by existing “LOT#” or create new Lot numbers during the goods receiving process.

Traceability is a key component in regulations and food safety standards - Aralco's Traceability Inventory module enables targeted and effective removal of recalled "bad" products from your warehouses and stores including identification of customers who have bought them for immediate recall. This prompt and accurate traceability helps you maintain both compliance and trust with your business partners and customers.

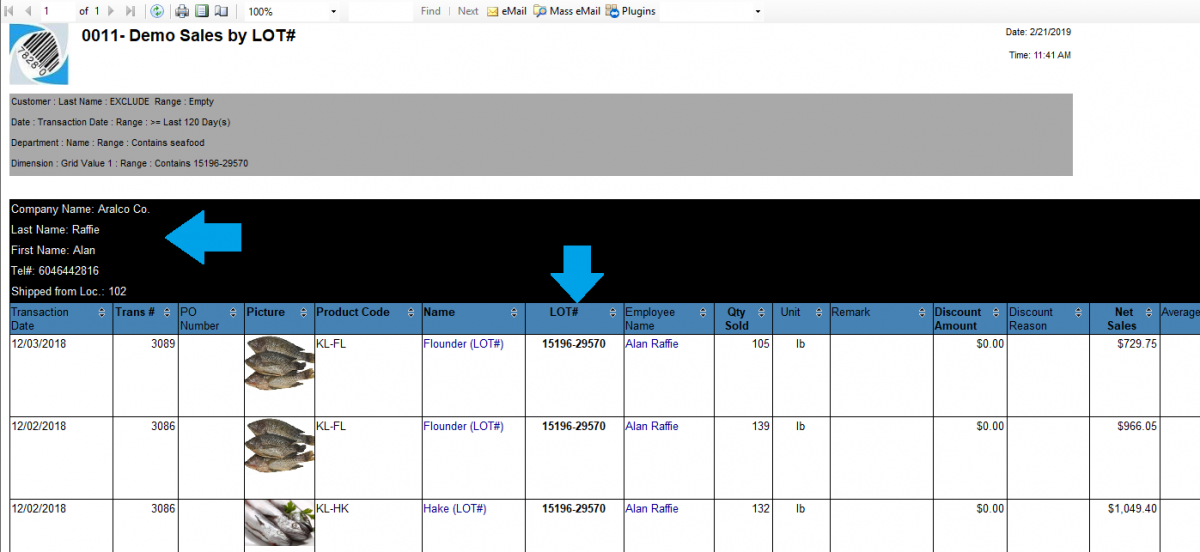

Managers can run reports on traceability at any time with real-time data or create user-definable reports to show when and where items were sold by lot number as well as who they were sold to with transaction reference, by whom and etc.

LOT NUMBERS

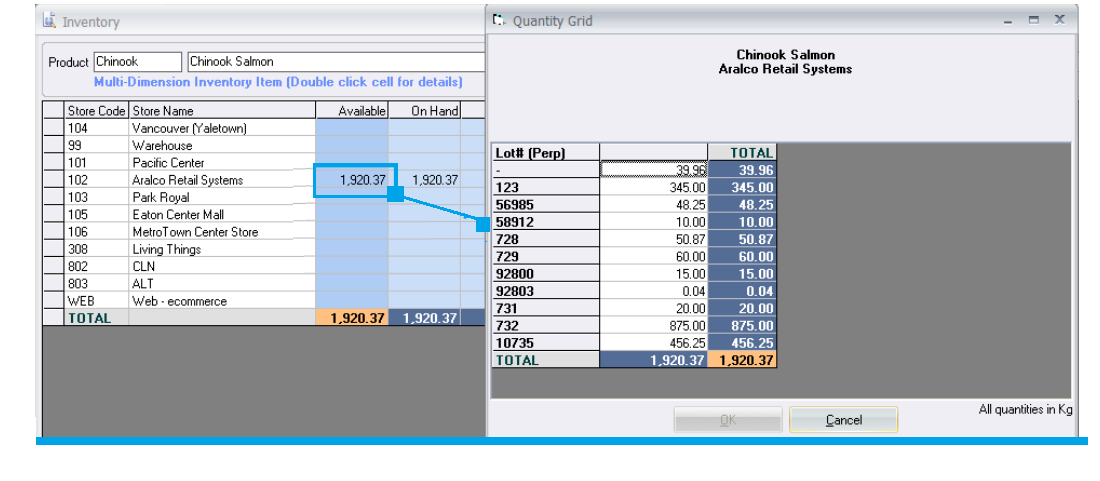

Once received into inventory, the items flagged with a LOT# requirement will appear in the inventory lookup as shown below, indicating each Lot# available in inventory, per location and quantities associated with each.

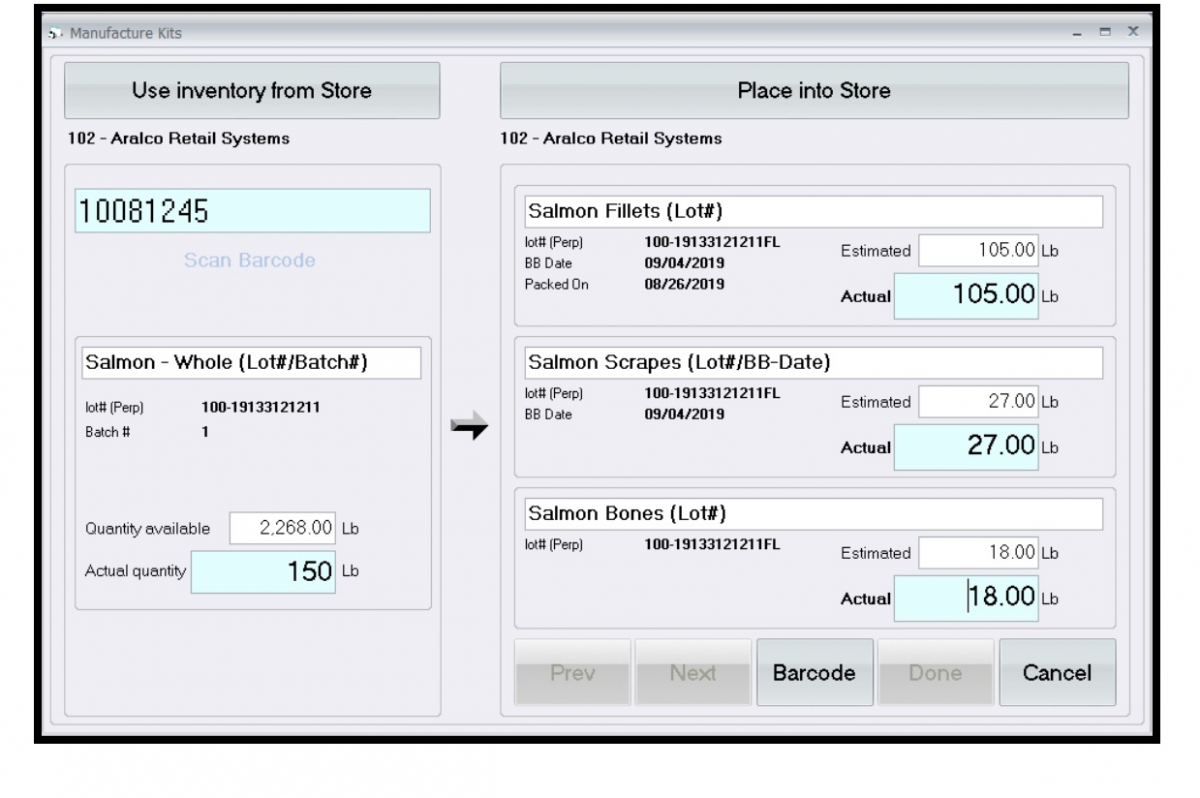

KIT SET MANUFACTURING -

PARTS EXPLOSION

An example of parts explosion is when a salmon gets processed into another product such as filets or smoked salmon etc. All fish parts, when broken down, are defined by percentage (e.g. 70% Filet, 12% Bones, 18% Scrapes) then, when cutting up a 12 lb salmon, the system will auto-calculate the parts after cuts are done and the fish is taken apart while assigning LOT#s to all parts.

All inventory “movements” such as Transfers, Adjustments, Sales, Return to Vendors, will be recorded by product code and LOT# associated and the system will automatically adjust those LOT#s’ accordingly.

REPORTING WHO BOUGHT THE LOT NUMBERS

Sales history below will show all sales movement of products associated with LOT#s and report filters will provide access to find specific LOT#’s sold to what customer by whom on what date and at which location: